How the CDS Solution Works

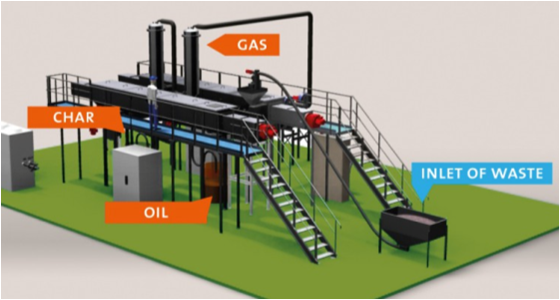

CDS systems are semi-mobile and containerized consisting of a pyrolysis module integrated with the necessary components to ensure continuous, turnkey operation. What is pyrolysis, you may be wondering, and how does it work?

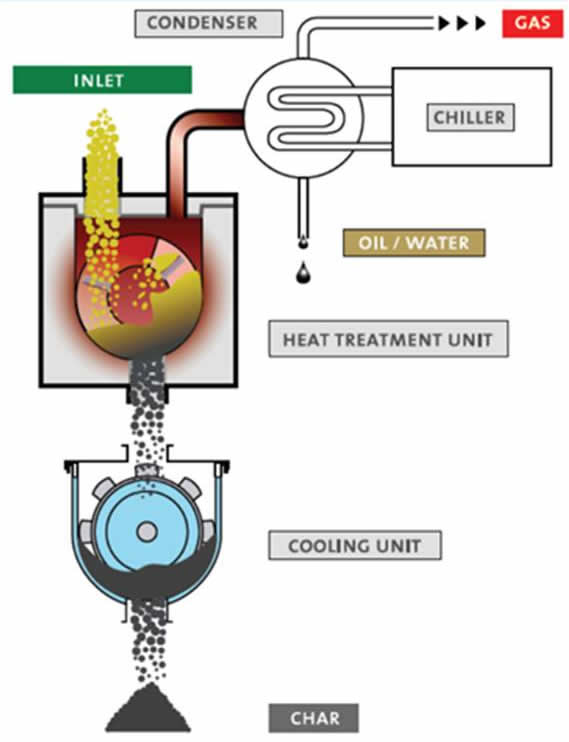

Pyrolysis is a type of thermochemical process that involves feeding feedstocks to temperatures between 250-800 degrees C in an oxygen free environment. See illustrations below.

In the words of one expert:

“The biomass is essentially ‘cooked’ [but not burned] until various lignin and cellulose products breakdown to produce a hydrogen-rich fuel stream that can either be combusted or condensed for energy generation. The high-carbon product that remains is biochar which has essentially been mined of hydrogen.”

– Dr. John Gaunt, Cornell University

An impressive variety of feedstocks can be continuously fed into the inlet and broken down into a stream of products and coproducts, each with substantial market value. See the illustrated production process for a description of the various stages of operation these systems use in practice.

This technology is fully mature and ready for immediate application

Here is an illustration of the process flow from raw feedstocks to the various coproducts:

Once operational, a full-sized unit produces its own power plus an additional thermal energy or electricity (for local consumption or via grid interconnection), where syngas can also be on-converted or condensed into various intermediary forms, such as methane, renewable diesel, etc., or some feedstocks also produce bio-oil (also called “pyrolysis oil”) that can be further processed into transportation fuels.

See Customers or Contact Us to register interest or inquire about system pricing, availability and delivery. Got questions? We can help.