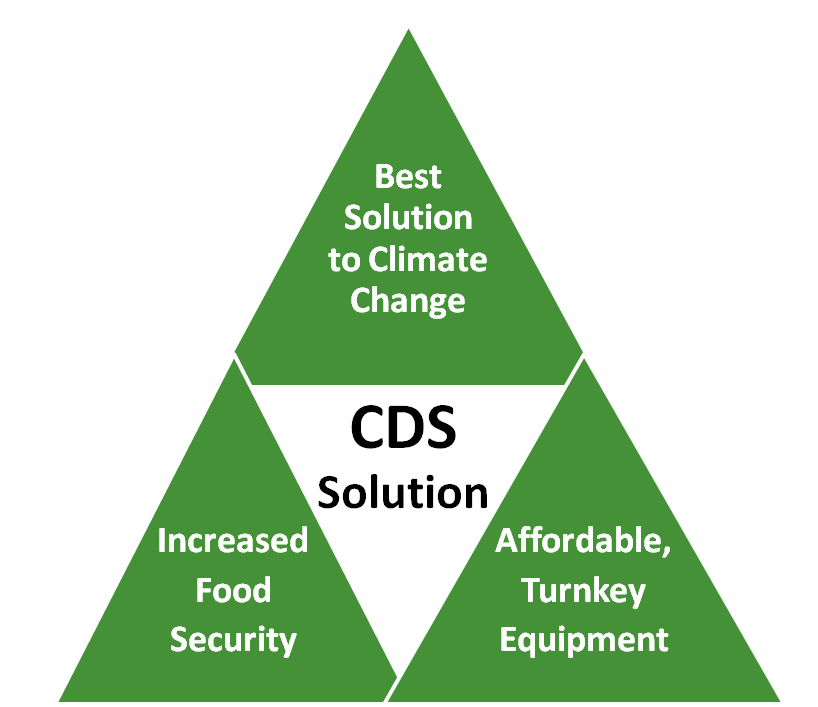

Turnkey Waste-to-Value solutions aimed at mitigating climate change

CDS offers the optimal solution for multiple problems in one, cost-effective, reliable, turnkey package.

We also provide technology integration, financing and resource management services, including help with selecting the optimal technical pathway for converting diverse waste streams into valuable, profitable products.

We have been in business over a decade; we really listen and can work with any stage project, located almost anywhere, with expertise in the major disciplines required to get projects built and delivering long-term benefits to all stakeholders.

Waste-to-Value Benefits

It starts with securing the feedstocks — the raw materials converted into products of value. With CDS systems, wastes from biomass to tires can be converted into customer-ready products that make money for the developers/owners while protecting our natural world. The conversion of wastes into assets can help restore or improve soil health, conserve or produce water, recapture nutrients (soils with a mix of biochar and compost, or other amendments, use less water for plant growth, and with less tillage generate less CO2 while increasing soil carbon).

Biomass-related resource recovery puts carbon to work on agricultural lands to increase food security while helping local farmers, improving yields, … or with industrial materials like waste rubber from tires, converts them back into products of service, such as new tires, without relying on fossil fuels or “virgin” carbon black, thus decreasing carbon footprints.

Unmanaged biomass waste causes disposal issues, such as release of methane or other greenhouse gases, or risk of wildfires, while controlling burning of wastes like rice straw or tires for energy affect air quality and health. If left unprocessed, the carbon and energy contained in these materials are lost.

CDS Main Roles

- Technology Integrators – help clients select the optimal pathway with pre-design, feasibility, and in some cases project co-development services

- Resource Management & Project Development Services, from owner’s engineering / representative, to EPC selection, project construction management or other services as required.

- Financing Agent: Through partner In3’s innovative project financing, we can perform Due Diligence and vetting to rapidly finance up to 100% of qualifying projects

About CDS cutting-edge Technologies

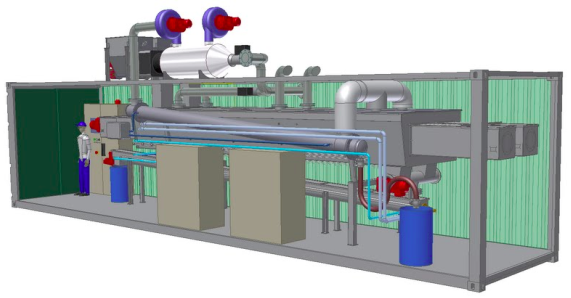

CDS modular, appropriate-scale systems feature commercially-proven pyrolysis technology and integrated components to process between 0.4 and 10+ tons of biomass or other materials per system per hour.

With biomass inputs, final products are high-quality biochar, process heat, syngas, pyrolysis oil, or other coproducts. Syngas and/or Pyrolysis oil can be onward converted to intermediary fuels, finished (“drop-in”) renewable fuels, or used to run a generator that produces electricity where there is favorable pricing.

With polymer / chemical compound (rubber or plastics) wastes, final products are fuels, elemental carbon (such as ASTM-compliant recovered Carbon Black), and other coproducts.

Systems can be configured to convert designated ties, biomass, crop wastes, sawdust, plastic, manure or Municipal Solid Waste/Sludge (MSW/MSS) into varying proportions of biochar, electricity, process heat, or oil with quick and simple automated adjustments. We offer both continuous and batch processing, with the standard systems.

CDS systems help resolve the growing and complex problems of accumulating atmospheric carbon, with a corresponding deficiency of carbon in the soil, especially depleted, tropical or subtropical soils, which often comes with waste biomass and other raw materials widely available in certain regions.

Waste is really just displaced resources — so, in a way, CDS helps decarbonize, returning that carbon to soils (where it belongs) and helps convert the liability of accumulating waste biomass into value streams for food and energy security. The lack of available food and energy (especially for cooking for or for access to electricity) is a notorious problem in many developing economies.

What problems does CDS solve?

Part of the solution: an innovative, “slow pyrolysis” core technology, which can be built into a semi-mobile, integrated, turnkey package, or set up at larger scale as a stationary platform. Such conversion is often co-located with Materials Recovery Facilities (MRFs) or constitute a separate facility based on the availability of a constant supply of feedstocks. These systems are available now and proven in many applications with diverse feedstocks.

All featured technology is fully mature and ready for immediate application.

How it works:

Operating Efficiency of CDS Containerized, Integrated Solution

One of the advantages of this technology is its relatively compact size and semi-portability: a complete system can be packaged in two 40-foot containers, delivered to a remote area with limited or no infrastructure, quickly set up and operated with minimum training. Systems can be relocated, if that becomes necessary, protecting the owner’s asset value.

Standard System Features:

- Can handle up to 5 tons dry matter per hourAvailable in various capacities ranging from, 0.4 – 4.8 tons/hr — appropriate to supply of available feedstock

- Reliably simple yet fully automated for continuous production

- Produces up to 15,000 tons of biochar/yr

- Semi-mobile with a 15 year life expectancy

- Generates its own electricity for remote installations, plus an excess up to 2MW depending on system size

Additional considerations:

- Compact and ready to use where biomass is available & labor is affordable

- Remote monitoring available

- Payback in as little as 2-3 years.

Industries Served

- Wood and bamboo saw mills

- Forestry, forest management, timber and lumber yards

- Food processing companies: rice, wheat, corn, coconut, palm, etc.

- Commercial agriculture and livestock

- Small business owners / independent entrepreneurs

- Waste haulers, aggregators; waste management

Pyrolysis utilizes multiple feedstocks:

- bamboo or other fast-growing biomass

- sawdust

- crop wastes

- food processing wastes

- municipal sewage sludge (MSS) or manure

- plastic

- tires (more on plastic & tire waste)

See Customers or call +1 831-761-3810 to register interest or inquire about system pricing, availability and delivery.